Our historical development of Wick Machinery GmbH.

1971

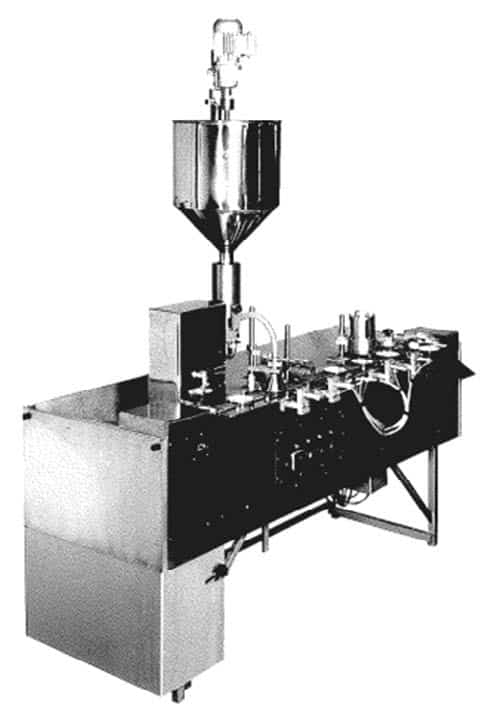

Josef Wick opens a mechanical workshop in Vienna with five co-partners and lays the foundation stone for the company.

When Josef Wick built the first fully automatic filling and capping machine in the same year as the company’s founding for cream cans, he had his son Andreas, who was only two years old at the time, test the first prototype. And because Andreas understood the handling right away, Josef Wick promptly said, “Look how user-friendly our systems are!” Perhaps you could already recognize the later managing director from Andreas’ shining eyes …

1974

Relocation to the larger location in Vienna’s 10th district.

In the early years, the “WICKinger”, as they were called by the operator of the Wiener Gasthaus Zur Teufelsmühle, went to lunch there every day. And because the WICKingers liked it so much, countless business ideas arose there – on the back of napkins.

1992

After difficult eighties, an application for insolvency has to be filed. Andreas Wick ventures a new start with a small group of loyal employees.

The history of Wick would be nothing without the unbeatable motivation, commitment and loyalty of all employees. It is noteworthy that many of the professionals decide to stay with the company until they retire and are happy to accept invitations to company parties afterwards.

1998

Schaefer, the renowned US manufacturer of filling machines for pharmaceutical capsules, has acquired a 10% stake in the company, which will henceforth operate under the name of Wick and Schaefer, due to the great success of Wick in this sector.

2003

The production of the first Wick filling machine for flexible infusion bags, which quickly becomes a great success.

When in-line fillers for bottles and canisters received a new, intuitive user interface and an even more flexible servo drive in 2004 and were delivered by a Wick project manager to a customer in Scunthorpe, England, this employee not only spoke proudly of the machine on his return, but also from now on raved about the unsurpassable taste of Scunthorpe Guinness at every company party.

2005

Wick-Machinery, together with TÜV, develops the first Atex-compatible servo filler for the chemical industry, which from then on has proven to be internationally successful.

2007

Due to the need for more production space, the location on Laaer-Berg-Straße will be closed and production will be split between the two current locations.

2008

With the development of the “Minican Universal”, a combination filling and closing machine for liquids, pastes and granulates, Wick-Machinery not only wins an award in the field of innovation, but also brings to life a hobbyhorse of the company that will be more in demand than ever in 2021.

2010

In 2010, Wick launched a new generation of filling machines for syringes, which were put into operation at a London customer in the same year. But the syringes had to be tested before delivery. And because the internal test runs took place in midsummer, real water fights were held in the garden behind the workshop with the previously filled syringes. It was worth it, because not only did everyone get wet, but customers in England were extremely satisfied a few weeks later.

2011

Entry into the flexible handling technology of non-stable bottles and cartridges.

2012

With the repurchase of Schaefer’s shares, the Wick family regained 100% ownership of the company.

2015

Wick-Machinery becomes a pioneer in the area of M2M communication.

2016

As part of an international R&D project, a self-contained compounding, mixing and filling system is being developed under the auspices of Wick-Machinery, which has been operated under the name PROCOMBO since 2017.

When Carolina Wick joined the company in 2016, she had one wish: to start at the grassroots level in order to get to know and understand all processes in Wick production right from the start. Since then, Carolina has not only completed technical and commercial training, but has also established itself as a driving force of the third generation, especially in the areas of communication and work methodology.

2019

Wick-Machinery is developing a new generation of syringe fillers that enable rapid conversion between different cannulas from different manufacturers.

2020

As part of an R&D project, Wick-Machinery is developing an aseptic formulation and filling system for single-batch pre-filled syringes in collaboration with research partners.

2021

Wick-Machinery is setting up a test bench with a simulation facility at the Oberlaa location in order to determine and document the closing, tightness and opening behavior of various packaging materials under different environmental conditions.

2022

With “format change at the push of a button”, format-free filling and closing machines are developed for different packaging materials, shapes and geometries.

2023

With “Flexo-Robot” a flexible, adaptive feeding and handling system for packaging materials and closures is to be developed.

„Wick-Machinery erfüllt Kundenwünsche auf höchstem technischen Niveau. Unsere Abfüll- und Verschließtechnik passt sich perfekt an Ihre Bedürfnisse an.”

Andreas Wick

Geschäftsleitung